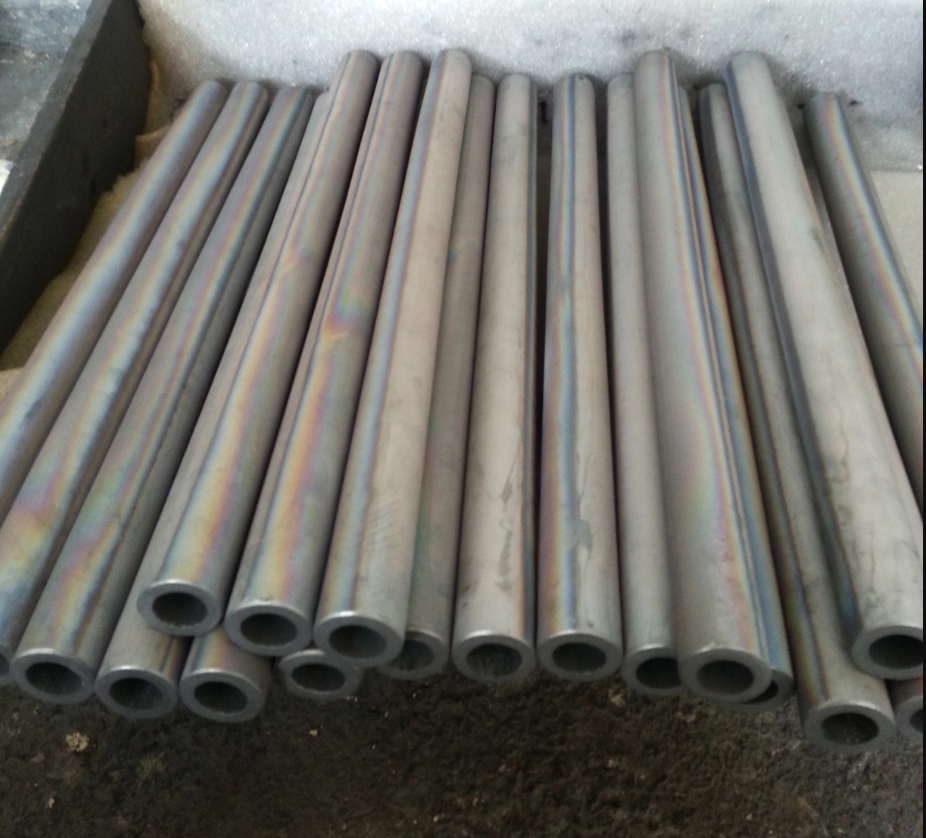

Description

Application

1. Molybdenum disilicide tube: Used as a bubbling tube for a glass tank kiln. In this case,

2. Two silicon molybdenum sealing tube: used for thermocouple protection tube for oxidation, reduction or corrosive atmosphere or temperature fluctuations in the environment, one is to prevent mechanical damage; the second is to protect the thermocouple from the measured medium Chemical corrosion, from the oxidizing atmosphere or reducing the harmful effects of the atmosphere, so that the thermocouple as close as possible to its best atmosphere. Therefore, the thermocouple must be protected from harmful atmosphere.

3. Two silicon-molybdenum probe: glass furnace for liquid level control, can replace platinum wire. In this case,

4. Molybdenum disilicide electrode: for fused glass, no water cooling.

Attributes

Molecular formula: MoSi2

Molybdenum Disilicide – Physicochemical Properties

Density: 5.5 to 5.6 g / cm3

Flexural strength: 15MPa (20 ℃)

Vickers hardness (HV): 570 kg / mm2

Porosity: 7.4%

Water absorption: 1.2%

Thermal elongation: 4%

Emission coefficient: 0.7 ~ 0.8 (800 ~ 2000 ℃)

Features

Molybdenum disilicide tube with high oxidation resistance, in high temperature atmosphere, the original surface of a layer of dense quartz SIO2 protective layer to prevent MOSI2 continue to oxidation. When the component temperature is greater than 1700 degrees, melting point of 1710 degrees SIO2 protective layer melting, due to the role of surface tension, SIO2 melting into droplets, and loss of protection. The SIO2 protective layer is regenerated when the element is used in an oxidizing atmosphere.